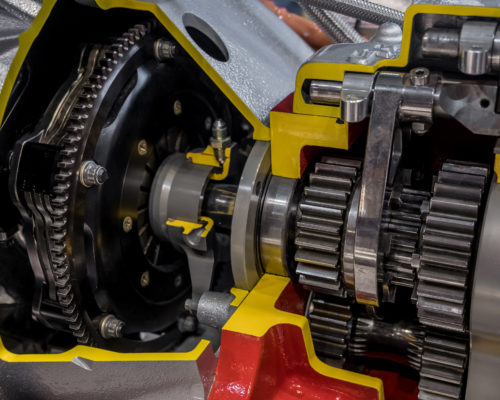

COLLABORATIVE DESIGN MAKES THE DIFFERENCE

To fulfill its promise of “maximum performance and productivity out of any engine or motor-driven machine,” Twin Disc relies upon the superior products, exceptional customer service and knowledgeable people at Grover Corporation.

Challenge

Twin Disc is a leading designer, manufacturer and distributor of power transmission equipment. The Twin Disc Quality Department reported they were experiencing excess ring wear on a specific transmission shaft. It was thought the rings with excessive wear could allow leakage, allowing the transmission to back feed pressure and not operate properly.

Solution

Grover Corporation’s sales and engineering personnel visited Twin Disc, reviewing all of the facts and inspecting the components. Grover personnel learned Twin Disc was performing additional operations to the rings prior to assembling the transmissions. These additional steps were affecting the design of the ring resulting in poor performance.

End-Result

In the end, the process change not only eliminated a pre-assembly process for Twin Disc, but it also ensures that the new design maintains its operational intent. This process of collaborative investigation and design is a prime example of Grover’s reliable and flexible design and manufacturing process.

Collaborative investigation and design is a prime example of Grover’s reliable and flexible design and manufacturing process.